DEPLOYING MACHINE VISION FOR IN-PROCESS METROLOGY

Arguably one of the most challenging tasks for automated inspection is the precision measurement of part features on-line and in-process covering 100% of product production. While the term metrology is often used in the context of off-line measurement of only a small statistical sampling of product, machine vision has been successfully implemented for similar measurements during the manufacturing process. One of the most common metrology applications for machine vision in quality control is gaging, for example. Because vision systems measure parts within a thousandth of an inch, the technology can be used for many applications traditionally handled by contact gaging.

Applications

Myriad challenges exist in the implementation of non-contact measurements during production including overcoming part presentation variation and the implementation of proper illumination. However, a key to success in metrology using machine vision is the proper specification of the image spatial resolution needed to achieve gauging reliability and repeatability relative to the desired measurement tolerance range. In many of today’s manufacturing environments, part or assembly tolerances can easily be at the micron level.

In a typical gaging application, a machine vision camera is mounted above or to the side of a part where it captures images of the part to be measured as it enters the field of view. The image is then analyzed using gaging software tools that calculate distances between different points in the image. Based on these calculations, the machine vision system determines if the part dimensions are within tolerance. If dimensions fall outside of that tolerance, the vision system sends a fail signal to a controller such as a PLC, which in turns triggers a reject mechanism to eject the product from the line.

While the application of machine vision for gaging and metrology is not new, advances in technology have enabled higher precision and more accurate measurement, even of tiny parts or features, than ever before. This includes the introduction of higher resolution and higher speed machine vision cameras such as those from Emergent Vision Technologies, which are offered in 5GigE, 10GigE, 25GigE, and 100GigE models that can deliver the accuracy and speed required for modern machine vision metrology applications. In addition to our cameras being available in a wide range of resolutions and frame rates for varying application needs, all models support an optimized GigE Vision Stream Protocol (GVSP) approach. This means that all Emergent cameras deliver zero-copy-image transfer and zero-data-loss imaging capabilities, which ensures efficient image transfer with minimal CPU overhead, which is crucial for real-time processing.

METROLOGY DEFINED

Metrology is defined as the scientific study of measurement. This is a discipline that emerges in line with scientific and technological advances. Metrology has three key facets:

- The definition of units of measurement that are fully accepted internationally. The meter is one example of a well-known unit of measurement

- The recognition of units of measurement via the use of scientific means. One example is the realization of the meter via the use of a laser. A laser distance meter measures the time that it takes a pulse of laser light to be reflected off a target and returned to the original sender. This is known as the “Time of Flight“ principle, and the method is known either as “Time of Flight” or “pulse” measurement. The distance between the meter and target is given by D = ct/2, in which c = the speed of light and t equals the amount of time for the round trip between meter and target.

- Establishing of the traceability chains via determining and documenting the value and accuracy of a measurement and disseminating that knowledge; for example, the documented relationship between the micrometer screw in a precision engineering workshop and a primary laboratory for optical length metrology.

AUTOMATED INSPECTION AND SORTING

In-process metrology is defined as a feedback control system, for the real-time monitoring of data in production, using smart sensors and actuators. Take the International Thermonuclear Experimental Reactor (ITER) project – a nuclear engineering and fusion research megaproject – as a high-profile example. This program intends to create energy, via a fusion process that will be similar to that of our Sun.

To guarantee the necessary performance, demanding dimensional tolerances have been defined for the ITER toroidal field (TF) coils. The process was divided into the following stages:

- Reception of the parts

- Insertion of the winding pack (WP) into the coil cases (CC)

- Closure welding

- Gap filling

- Final machining

During each of the production stages, metrology inspections were carried out to review the compliance with the following defined requirements:

- Fiducial marker measurement of at least two markers a surface mounted component.

- Gap analysis to identify and evaluate the gaps between their actual performance and their potential, desired performance in order that plans and strategies are able to be developed for filling those gaps.

- Virtual prototyping fit that will require simulation tools, which will be used to evaluate circuit functionality before prototyping.

Analysis of welding distortion, which refers to a change in the shape or size of a welded structure.

METROLOGY IN MACHINE VISION

Machine vision cameras today are deployed in an increasingly wide range of inspection and automation applications. Innovations in speed and resolution have opened the door to new opportunities when it comes to achieving higher productivity, improved quality, safety control, and boosting overall efficiency amidst a persisting labor shortage, and driving revenue in a highly competitive manufacturing scenario.

Manufacturers may choose to opt for machine vision-based gaging for any number of reasons, including speed. With contact gaging, it is not possible to keep pace with high-throughput production lines because measurements are typically performed on an audit basis. Machine vision systems, on the other hand, operate at the high speeds required for the production lines of today. Designed for in-line, 100% inspection, machine vision systems can perform thousands of measurements per minute. In addition, vision-based gaging requires no contact with the parts being measured, which prevents damage to parts and eliminates maintenance associated with wear and tear on mechanical gage surfaces.

Whether a customer asks for faster speeds to increase throughput or higher resolution for the accurate measurement of extremely small parts or features, Emergent Vision Technologies offers a comprehensive set of GigE Vision camera options that offer zero-copy image transfer and zero-data-loss imaging capabilities. Cameras in our 5GigE Eros and 10GigE HR series, for example, leverage the following Sony Pregius S CMOS image sensors:

- 5.1MP IMX547: HE-5000-SBL 5GigE camera (45.5fps), HR-5000-SBL 10GigE camera (99fps)

- 8.1MP IMX546: HE-8000-SBL 5GigE camera (36.5fps), HR-8000-SBL 10GigE camera (73fps)

- 12.4MP IMX545: HE-12000-SBL 5GigE camera (34fps), HR-12000-SBL 10GigE camera (68fps)

- 16.13MP IMX542: HE-16000-SBL 5GigE camera (26fps), HR-16000-SBL 10GigE camera (52fps)

- 20.28MP IMX541: HE-20000-SBL 5GigE camera (21.5fps), HR-20000-SBL 10GigE camera (43fps)

- 24.47MP IMX540: HE-25000-SBL 5GigE camera (17.5fps), HR-25000-SBL 10GigE camera (35fps)

The 25GigE Bolt series also leverages the 5.1MP IMX537 in its HB-5000-SB (269fps), 8.1MP IMX536 in its HB-8000-SB (201fps), 12.3MP IMX535 in its HB-12000-SB (192fps), 20.28MP IMX531 in its HB-20000-SB, and the 24.47MP IMX530 in its HB-25000-SB (98fps). In addition, while not all applications may require ultra-high speeds or 100MP+ resolution, Emergent offers the following models:

- 25GigE Bolt HB-127-S: 127.7MP Sony IMX661, 17fps

- 100GigE Zenith HZ-10000-G: 10MP Gpixel GSPRINT4510, 1000fps

- 100GigE Zenith HZ-21000-G: 21MP Gpixel GSPRINT4521, 542fps

- 100GigE Zenith HZ-100-G: 103.7MP Gpixel GMAX32103, 24fps

Use case examples for metrology in manufacturing include:

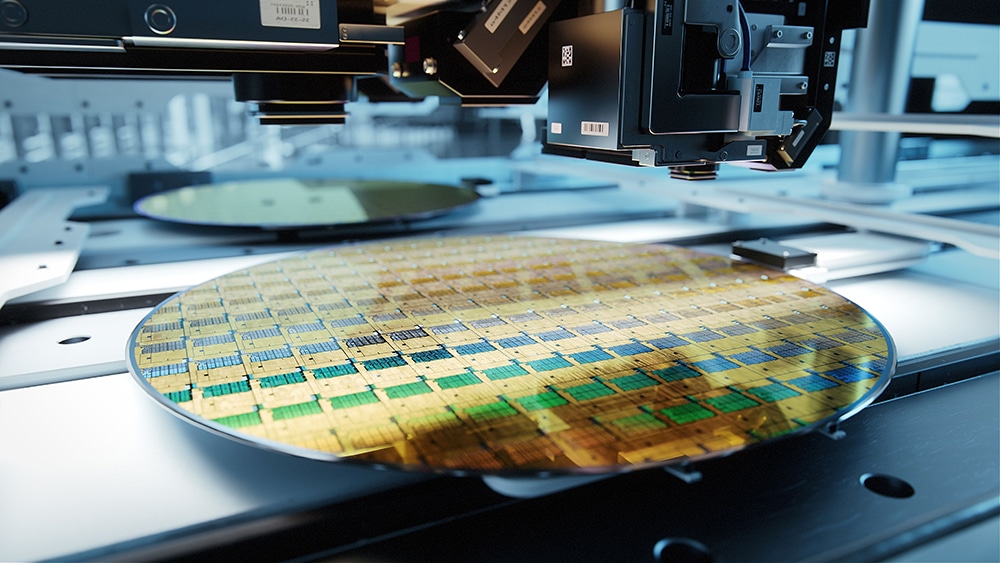

WAFER INSPECTION:

Semiconductor manufacturer KLA has a wafer inspection and metrology system that is ideal for advanced wafer level packaging. This capability is also able to provide integrated circuit (IC) manufacturers with the data necessary for increasing their yields via traceability within the complex overall manufacturing process. KLA’s CIRCLTM platform is an adaptable, all-surface wafer inspection platform; its front-side patterned wafer inspection system is usually used for high throughput inline macro defect inspection. The system measures and inspects simultaneously, which helps customers to recognize and resolve excursions as they happen.

CRITICAL DIMENSION UNIFORMITY (CDU):

CDU measures the amount of line width variation from the average and is typically defined mathematically as 3X the corrected sample standard deviation of a group of line width measurements. Wafer CDU is an important parameter that will outline the performance of lithography process control. Within the framework of self-aligned quadruple patterning (SAQP), the final CDU and pitch walking (the pitch variation between features) are closely related to the profile and CDU of spacer deposition.

To improve wafer CDU, lithographers must know quantitatively the contributions of shot-dependent factors and wafer-dependent factors, respectively. The overall wafer CDU can usually be broken down into two parts, among-shot uniformity, or inter-field uniformity, and within-shot uniformity, or intra-field uniformity. The way to calculate intra-field uniformity is to calculate linewidth variation across the shot with each data point being averaged over difference shots.

The method of calculating inter-field uniformity may be different. One method calculates the line width variation across the wafer while having each data point deducted from the intra-field component. The other method is to calculate the line width variation, among different shots, for each location in the shot and then to average the results over all locations. When comparing the CDU results calculated by the two statistical methods, it was discovered that the differences were more significant when the sample was small. In addition, the data measured on the wafers is used to accurately illustrate the differences.

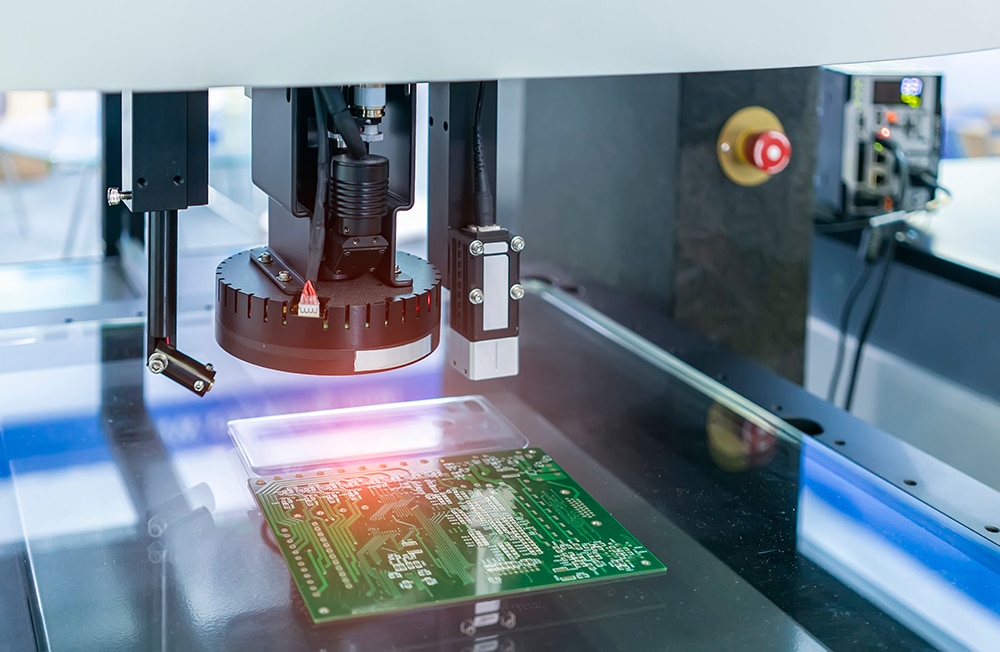

PRINTED CIRCUIT BOARD (PCB) INSPECTION:

KLA also has a vast portfolio of process control solutions for printed circuit board manufacturing, including a fully automated optical inspection (AOI) system that provides advanced defect inspection and panel metrology systems for 2D and 3D measurements. AOI systems such as this help IC substrate and PCB manufacturers find, classify, and identify defects on all classes of PC boards.

Fig. 1 Machine vision metrology systems can be deployed for the inspection of printed circuit boards.

KLA has multi-mode metrology systems which enable a wide variety of measurement applications for test and inline panels. The result of critical inspection and metrology information is enhanced by artificial intelligence (AI) and machine learning (ML). This enables engineers to detect, resolve and monitor critical yield wandering, which leads to higher production yields and a faster yield ramp.

GPUDIRECT: ZERO-DATA-LOSS IMAGING

For all its cameras, Emergent leverages an optimized GigE Vision approach and Ethernet infrastructure for reliable and robust data acquisition and transfer, with best-in-class performance instead of relying on proprietary or point-to-point interfaces and image acquisition boards. Emergent supports direct transfer technologies such as NVIDIA’s GPUDirect, which enables the transfer of images directly to GPU memory. The technology mitigates the impact of large data transfers on the system CPU and memory, and instead utilizes more powerful GPU capability for data processing, while maintaining compatibility with the GigE Vision standard and interoperability with compliant software and peripherals.

ZERO-COPY IMAGING FOR MACHINE VISION IN METROLOGY APPLICATIONS

Within GigE Vision, one of the problems that has led to the use of Transmission Control Protocol (TCP) or remote direct memory access (RDMA) and RDMA over Converged Ethernet (RoCE) is the need to dissect Ethernet packets at the receiver to provide the image data to the application in contiguous form, which requires splitting off Ethernet packet headers. Doing so is possible using software, but comes at a performance cost with triple the memory bandwidth and a higher CPU utilization, which is something that RDMA users tout when discussing pros and cons of traditional GigE Vision and RDMA.

Emergent Vision Technologies leverage a zero-copy image transfer approach, which has become a must-have requirement for top performance in high-speed imaging. This approach minimizes CPU and memory bandwidth by using built-in splitting features available in current network interface cards. This animation shows the zero-copy memory bandwidth usages of a system using the optimized GigE Vision Stream Protocol (GVSP) for zero-copy image transfer. The first part of the animation shows that the system is not optimized and the buffer in the NIC overflows, while the second part shows data flowing freely and reliably via zero-copy and system optimization.

SUMMARY

Machine vision technology such as high-speed, high-resolution cameras and software helps meet the demands of higher throughput rates, improved product quality, and increased yields. Manufacturers will continue to rely on machine vision systems as a non-contact method to measure parts due to its ability to provide 100% inspection, measuring parts at high speeds with a high degree of repeatability – some of which cannot even be measured using mechanical gauges. In metrology applications where speed, resolution, and real-time processing are paramount, Emergent Vision Technologies GigE Vision cameras can be reliably deployed for reliable image transmission with no dropped packets or frames.

EMERGENT MACHINE VISION CAMERAS FOR METROLOGY APPLICATIONS

| Model | Chroma | Resolution | Frame Rate | Interface | Sensor Name | Pixel Size | |

|---|---|---|---|---|---|---|---|

|

HE-5000-SBL-M | Mono | 5.1MP | 45.5fps | 1, 2.5, 5GigE | Sony IMX547 | 2.74×2.74μm |

|

HE-5000-SBL-C | Color | 5.1MP | 45.5fps | 1, 2.5, 5GigE | Sony IMX547 | 2.74×2.74μm |

|

HE-8000-SBL-M | Mono | 8.1MP | 36.5fps | 1, 2.5, 5GigE | Sony IMX546 | 2.74×2.74μm |

|

HE-8000-SBL-C | Color | 8.1MP | 36.5fps | 1, 2.5, 5GigE | Sony IMX546 | 2.74×2.74μm |

|

HE-12000-SBL-M | Mono | 12.4MP | 34fps | 1, 2.5, 5GigE | Sony IMX545 | 2.74×2.74μm |

|

HE-12000-SBL-C | Color | 12.4MP | 34fps | 1, 2.5, 5GigE | Sony IMX545 | 2.74×2.74μm |

|

HE-16000-SBL-M | Mono | 16.13MP | 26fps | 1, 2.5, 5GigE | Sony IMX542 | 2.74×2.74μm |

|

HE-16000-SBL-C | Color | 16.13MP | 26fps | 1, 2.5, 5GigE | Sony IMX542 | 2.74×2.74μm |

|

HE-20000-SBL-M | Mono | 20.28MP | 21.5fps | 1, 2.5, 5GigE | Sony IMX541 | 2.74×2.74μm |

|

HE-20000-SBL-C | Color | 20.28MP | 21.5fps | 1, 2.5, 5GigE | Sony IMX541 | 2.74×2.74μm |

|

HE-25000-SBL-M | Mono | 24.47MP | 17.5fps | 1, 2.5, 5GigE | Sony IMX540 | 2.74×2.74μm |

|

HE-25000-SBL-C | Color | 24.47MP | 17.5fps | 1, 2.5, 5GigE | Sony IMX540 | 2.74×2.74μm |

|

HR-5000-SBL-M | Mono | 5.1MP | 99fps | 10GigE SFP+ | Sony IMX547 | 2.74×2.74μm |

|

HR-5000-SBL-C | Color | 5.1MP | 99fps | 10GigE SFP+ | Sony IMX547 | 2.74×2.74μm |

|

HR-8000-SBL-M | Mono | 8.1MP | 73fps | 10GigE SFP+ | Sony IMX546 | 2.74×2.74μm |

|

HR-8000-SBL-C | Color | 8.1MP | 73fps | 10GigE SFP+ | Sony IMX546 | 2.74×2.74μm |

|

HR-12000-SBL-M | Mono | 12.4MP | 68fps | 10GigE SFP+ | Sony IMX545 | 2.74×2.74μm |

|

HR-12000-SBL-C | Color | 12.4MP | 68fps | 10GigE SFP+ | Sony IMX545 | 2.74×2.74μm |

|

HR-16000-SBL-M | Mono | 16.13MP | 52fps | 10GigE SFP+ | Sony IMX542 | 2.74×2.74μm |

|

HR-16000-SBL-C | Color | 16.13MP | 52fps | 10GigE SFP+ | Sony IMX542 | 2.74×2.74μm |

|

HR-20000-SBL-M | Mono | 20.28MP | 43fps | 10GigE SFP+ | Sony IMX541 | 2.74×2.74μm |

|

HR-20000-SBL-C | Color | 20.28MP | 43fps | 10GigE SFP+ | Sony IMX541 | 2.74×2.74μm |

|

HR-25000-SBL-M | Mono | 24.47MP | 35fps | 10GigE SFP+ | Sony IMX540 | 2.74×2.74μm |

|

HR-25000-SBL-C | Color | 24.47MP | 35fps | 10GigE SFP+ | Sony IMX540 | 2.74×2.74μm |

|

HB-5000-SB-M | Mono | 5.1MP | 269fps | 25GigE SFP28 | Sony S IMX537 | 2.74×2.74μm |

|

HB-5000-SB-C | Color | 5.1MP | 269fps | 25GigE SFP28 | Sony S IMX537 | 2.74×2.74μm |

|

HB-8000-SB-M | Mono | 8.1MP | 201fps | 25GigE SFP28 | Sony S IMX536 | 2.74×2.74μm |

|

HB-8000-SB-C | Color | 8.1MP | 201fps | 25GigE SFP28 | Sony S IMX536 | 2.74×2.74μm |

|

HB-12000-SB-M | Mono | 12.4MP | 192fps | 25GigE SFP28 | Sony S IMX535 | 2.74×2.74μm |

|

HB-12000-SB-C | Color | 12.4MP | 192fps | 25GigE SFP28 | Sony S IMX535 | 2.74×2.74μm |

|

HB-16000-SB-M | Mono | 16.13MP | 145fps | 25GigE SFP28 | Sony S IMX532 | 2.74×2.74μm |

|

HB-16000-SB-C | Color | 16.13MP | 145fps | 25GigE SFP28 | Sony S IMX532 | 2.74×2.74μm |

|

HB-20000-SB-M | Mono | 20.28MP | 100fps | 25GigE SFP28 | Sony S IMX531 | 2.74×2.74μm |

|

HB-20000-SB-C | Color | 20.28MP | 100fps | 25GigE SFP28 | Sony S IMX531 | 2.74×2.74μm |

|

HB-25000-SB-M | Mono | 24.47MP | 98fps | 25GigE SFP28 | Sony S IMX530 | 2.74×2.74μm |

|

HB-25000-SB-C | Color | 24.47MP | 98fps | 25GigE SFP28 | Sony S IMX530 | 2.74×2.74μm |

|

HB-127-S-M | Mono | 127.7MP | 17fps | 25GigE SFP28 | Sony IMX661 | 3.45×3.45µm |

|

HB-127-S-C | Color | 127.7MP | 17fps | 25GigE SFP28 | Sony IMX661 | 3.45×3.45µm |

|

HZ-10000-G-M | Mono | 10MP | 1000fps | 100GigE QSFP28 | Gpixel GSPRINT4510 | 4.5×4.5µm |

|

HZ-10000-G-C | Color | 10MP | 1000fps | 100GigE QSFP28 | Gpixel GSPRINT4510 | 4.5×4.5µm |

|

HZ-21000-G-M | Mono | 21MP | 542fps | 100GigE QSFP28 | Gpixel GSPRINT4521 | 4.5×4.5µm |

|

HZ-21000-G-C | Color | 21MP | 542fps | 100GigE QSFP28 | Gpixel GSPRINT4521 | 4.5×4.5µm |

|

HZ-100-G-M | Mono | 103.7MP | 24fps | 100GigE QSFP28 | Gpixel GMAX32103 | 3.2×3.2µm |

|

HZ-100-G-C | Color | 103.7MP | 24fps | 100GigE QSFP28 | Gpixel GMAX32103 | 3.2×3.2µm |

For additional camera options, check out our interactive system designer tool.